You Can’t See It—But Can You Afford to Ignore It?

Your seawall might look fine on the outside — but if the ground behind it is sinking, soft, or forming small sinkholes, trouble is brewing below the surface. The only structural element that keeps a seawall upright is the tie back bars and the “Deadman” anchors that they are tied into deep in the soil behind the seawall. If your soil is loose and contains voids, the Deadman anchors will shift seaward and cause seawall failure.

At Seawall Medic, we repair your seawall without tearing up your yard or replacing the entire structure. Using expanding polyurethane foam, we inject deep into the soil to fill hidden voids, stop erosion at its source, and restore stability—quickly and cleanly.

You might not realize it, but erosion behind your seawall could already be underway.

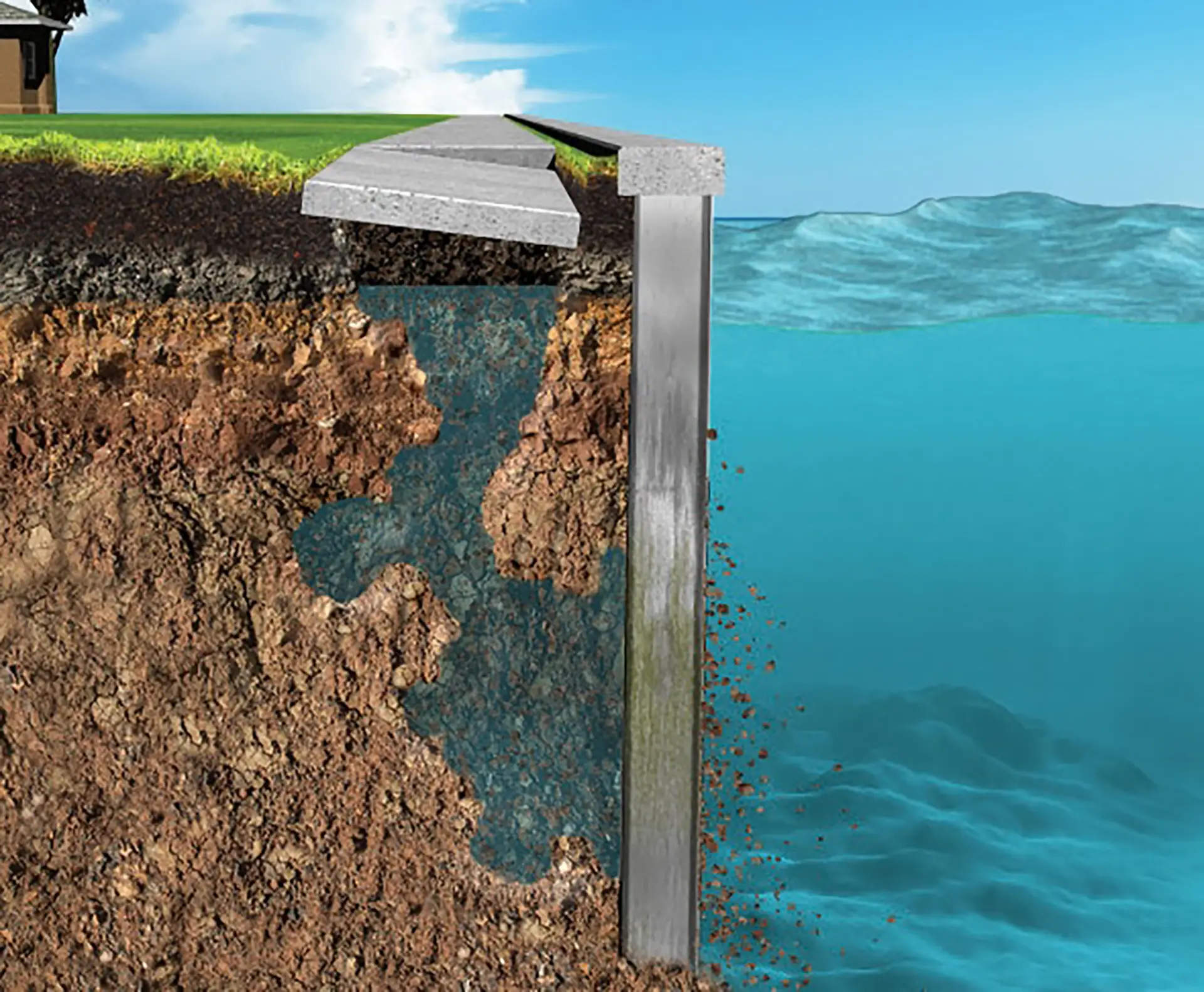

Over time, water seeps through cracks in your seawall and washes out the soil behind it. This creates dangerous voids, sinkholes, and eventually, structural failure.

You might notice:

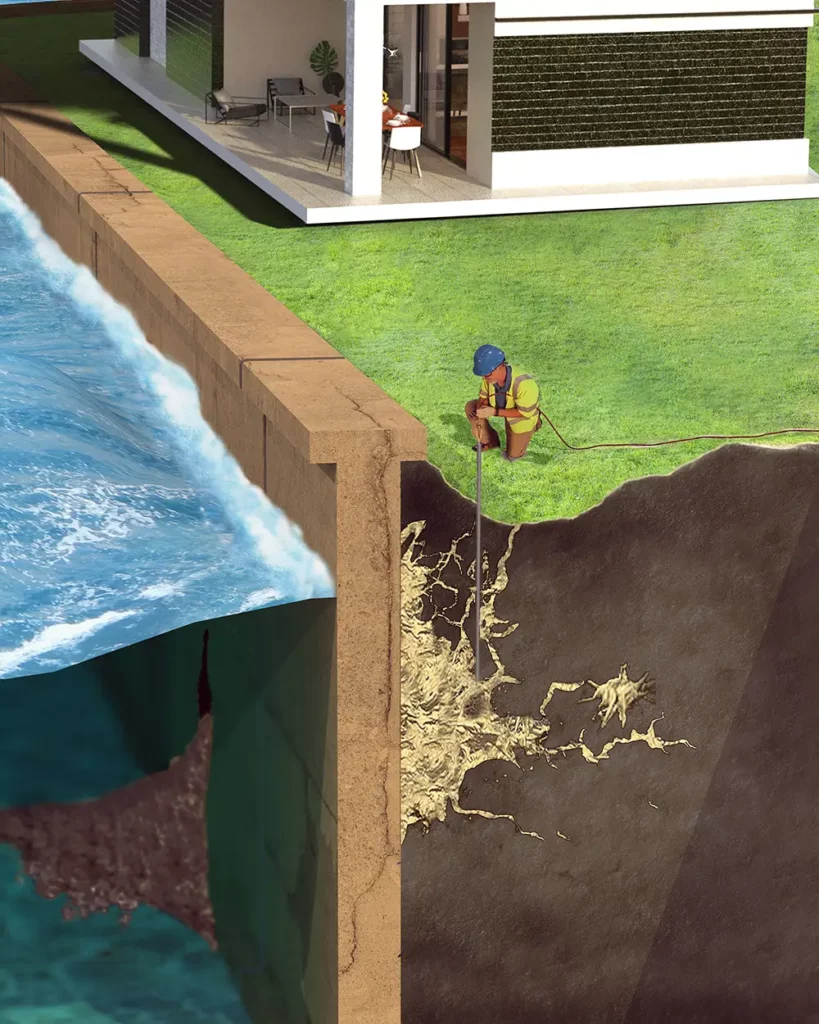

We evaluate your seawall and use probes to identify void and unstable areas behind the wall.

Then, we insert the injection probe rod deep into soil on the landward side of seawall into targeted area.

We inject Hydrophobic expanding polyurethane foam deep into the soil. The foam:

The foam fully expands and cures within minutes. Any excess foam in the water that migrated through joints or cracks in the wall will be cleaned up. We cut off excess foam that came through the wall or expanded through the top of the soil or grass. Any exposed areas of foam in the yard gets covered with sand to allow for expedited sod re-growth.

You don’t have to guess. Let us inspect your seawall and we will report any issues in a comprehensive work proposal.

Polyurethane foam injection is an innovative repair technique where a specialized expanding foam is injected into the ground behind a seawall to stabilize it. Technicians insert an injection rod through the ground immediately behind it and pump liquid polyurethane resin into unstable soil areas. Once injected, the liquid quickly expands into a foam, filling any voids, cracks, or gaps in the soil. The expanding foam pushes into loose soil and hardens, essentially gluing the soil particles together and creating a solid, water-resistant barrier behind the wall. This process both seals leaks (stopping water from seeping through the wall) and strengthens the ground, which is pivotal in supporting the seawall via the tiebacks and deadman anchors. The foam sets up in minutes and reaches full strength quickly, forming a dense, stable matrix of material that resists further erosion.

Yes – when done with the proper materials, foam injection is considered environmentally safe and non-disruptive. The polyurethane foam used for seawall stabilization is typically a closed-cell, inert material once it cures. This means it won’t leach harmful chemicals into the surrounding soil or water. In fact, the Polyurethane we use NCFI Terra-Lok 24-120 is specifically formulated to be environmentally friendly and have been tested to meet safety standards. NCFI Terra-Lok 24-120 is regularly used in sensitive canal and coastal areas. The foam is injected in a controlled manner, so it stays mostly within the target area (filling voids and sealing the wall). However, due to the fact that this method is not a gimmick we expect and plan for foam leakage into the waterway via cracks, panel seams and any other gaps often times by installing a turbidity barrier (floating barrier with curtains to prevent debris escaping) in the water to catch the foam that makes it through these gaps. This makes it easy for the now hardened/cured foam to be scooped out of the water and cleanup. Additionally, because foam injection doesn’t require heavy machinery or excavation, there’s minimal disturbance to the shoreline habitat or your property’s landscape during the repair process. You get a stabilized seawall without the mess of concrete trucks or the risk of wet concrete runoff. In short, NCFI Terra-Lok 24-120 is designed to be property-friendly and eco-friendly, giving you peace of mind about safety.

Foam injection is an ideal solution when you notice early signs of soil erosion or voids behind a seawall, but the wall itself is still mostly intact. If you see things like minor leaning, cracks with soil loss, or small sinkholes forming behind the seawall, that’s a great time to use foam stabilization. It’s most effective for preventing an impending failure – for example, when drainage issues or undermining are starting to cause soil voids, but the seawall hasn’t experienced any major failure. By injecting foam, you can fill those voids and re-support the structure before it worsens. Foam is also a good choice if the seawall is difficult to access with heavy equipment (since foam is installed using hoses and inceyion rod via small holes in the soil or access holes drilled thru harder substrates that may be covering the soil). However, foam injection might not be sufficient if the seawall has major structural damage – like large broken chunks, a completely sheared-off wall, or severely corroded rebar throughout. In those cases, foam can be part of the repair (to stabilize soil) but you may also need to repair or replace physical components (e.g. new tie-backs, panel or pile replacements or reinforcement). In summary, use foam injection as a proactive repair for erosion and minor movement issues. It’s a cost-effective way to extend the life of a seawall that is starting to struggle but hasn’t failed outright. Seawall Medic stands out in the industry as a comprehensive seawall repair company as we are able to not just perform soil stabilization but are able to repair to the highest standards others structural components of the seawall i.e. cap, panel, pilings, tiebacks, walers and footers.

Polyurethane foam injection offers several advantages over old-school seawall repair methods:

In short, foam injection is faster, cleaner, and often more effective at stopping erosion compared to old methods like heavy concrete pours. It addresses the root cause (voids and leaks) without introducing new problems, making it a preferred modern solution for many seawall repairs.

Hardly at all. One big benefit of polyurethane foam repair is that it’s minimally invasive and quick, meaning very little disruption to your property or routine. Seawall Medic utilizes a unique custom built all terrain motorized workstation which has all pump equipment, hose reel and generator built on to it. The workstation can fit thru most standard size doorways or fence gates – no need for large excavators or pile drivers. In many cases, the work crew can operate in a tight area along the seawall without tearing up landscaping. No major digging is required, since the foam travels underground to fill voids. Most foam injection projects for residential seawalls are completed in just a day or two. This means if it’s at your home, you won’t have a long construction project – and if it’s at a business or marina, operations can continue with minimal interruption. There’s also usually no heavy noise or mess beyond foam that comes out of the wall on the seaward side and sometimes foam that comes out of the ground at the point of injection when overfilled (both of which get cleaned up rather quickly). By contrast, a traditional seawall replacement might involve heavy machinery, loud construction, and a lot of debris over several weeks. With foam injection, when the job is done, you’re typically left with just small areas covered with sand that we place over any overfill areas after we remove the excess foam to facilitate grass re-growth – hardly any sign that repair work even took place. It’s one of the most property-friendly repair methods available.

A properly performed foam injection project is intended to be a long-lasting solution, not just a quick patch. The foam material itself is durable and inert once it cures – it doesn’t break down in soil. Seawall Medic offers up to a 10-year warranty for our soil stabilization work. In fact, by filling voids and stopping leakage, foam injection often significantly extends the life of the seawall. Some estimates suggest it can double the remaining lifespan of a wall that’s starting to fail, because it shores up the structure and prevents further rapid erosion. The foam effectively strengthens the seawall’s support system: it solidifies the ground that the wall presses against and ensures the tiebacks and deadman anchors stay in place and don’t shift due to erosion. However, it’s important to note that while foam greatly stabilizes the soil and seals cracks, it doesn’t replace the physical concrete or steel if those elements are structurally compromised. So, foam will reinforce and stabilize a weakened seawall, but if a wall is crumbling or has broken components, those may still need repair or reinforcement separately. Overall, you can expect a foam-injected seawall to perform like a much younger wall – solid and supported – for many years to come, especially if you continue to maintain the seawall properly after the repair.

Waiting Costs More, erosion accelerates with time, leading to bigger problems and bigger bills. Foam injection offers a non-invasive fix—faster, cleaner, and far less costly than rebuilding your seawall.